As geodesic domes gain popularity as both glamping structures and permanent residences, builders and homeowners in British Columbia are increasingly navigating the BC Energy Step Code for compliance. Unlike conventional homes, domes are unique in form and require specialized considerations—but the process for proving energy efficiency and meeting step code requirements is both achievable and replicable.

Here’s a breakdown of what’s involved in demonstrating BC Step Code compliance for domes, based on expert guidance from energy advisor Liam Butters and Phoenix Domes' real-world application.

Understanding Step Code and Its Applicability to Domes

The BC Energy Step Code is a provincial standard that requires new construction to meet specific energy efficiency performance levels. Unlike traditional prescriptive code, Step Code is performance-based—making it more accommodating to unconventional structures like domes.

Key Components to Prove Step Code Compliance

To ensure your dome meets compliance standards, here’s what you need:

1. Energy Modeling

A certified energy advisor creates a digital model of your dome using architectural drawings. For domes, this includes:

- 3D modeling of the entire structure (volume, surface area, windows, foundation, etc.)

- Assigning properties to each section (e.g., insulation levels, glass types)

- Simulating how heat flows through the structure

- Factoring in mechanical systems: heating, water heating, ventilation, and energy recovery

For Phoenix Domes, existing SketchUp models or DWG files of each dome (including foundations and standard window placements) can be directly used in the modeling process, which speeds up setup time.

2. Insulation Requirements

Spray foam insulation is a common and effective solution in domes. To comply:

- The energy advisor calculates the minimum required insulation thickness for each surface type.

- The spray foam contractor must be capable of applying insulation to these exact specifications with consistency.

Because domes are inherently efficient shapes—minimizing surface area relative to volume—they often require less insulation than traditional homes to achieve the same performance targets.

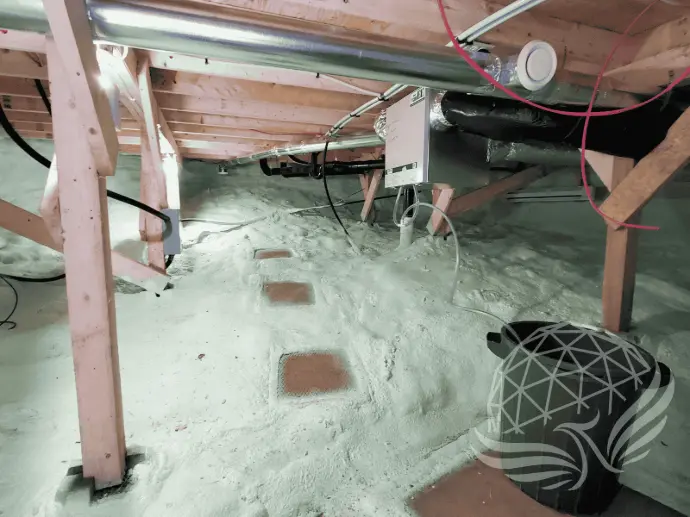

3. Airtightness & Blower Door Testing

One of the most important performance metrics is airtightness. Every home undergoing Step Code certification must pass a blower door test, which measures air leakage.

For domes:

- Full spray foam interiors provide an air-impermeable membrane, simplifying airtightness.

- Blower door testing typically takes 15–30 minutes.

- If leakage is found, additional sealing work may be needed—but domes tend to perform well due to their continuous surface geometry.

An on-site test is required for final compliance and can be arranged via a local energy advisor network.

4. On-Site Verification

In addition to modeling, the following is needed:

- Site visit by a certified energy advisor, especially for the final blower door test.

- As-built documentation (as-built energy reports, insulation installation, mechanical systems).

The advisor ensures that what's built matches the model and meets all performance thresholds.

File Formats and Data Needed

To begin modeling, the advisor will need:

- SketchUp (.skp) or DWG files of the dome and foundation

- Window and door placement details

- Mechanical system specifications (if known)

Even PDFs can work, but editable formats streamline the modeling process.

Estimated Costs & Timeline

Costs for energy modeling and on-site testing vary by region and complexity but typically include:

- Initial modeling and report generation

- On-site blower door test

- Final compliance documentation

For multiple dome projects across BC, having a known advisor like Liam familiar with the design can save time and reduce costs. Local partners across the province (including in Smithers, Kamloops, and Penticton) can perform the on-site portions.

Why Domes Are Well-Suited to Step Code

Domes naturally align with Step Code performance goals:

- High energy efficiency due to low surface-area-to-volume ratio

- Excellent airtightness when spray foam is used

- Minimal thermal bridging due to their geometric continuity

These factors make domes potentially easier to certify than many conventional builds—if the right modeling and verification steps are followed.

Conclusion: A Path to Permitting Dome Homes in BC

While building a permanent geodesic dome in BC comes with added planning and documentation, Step Code compliance is entirely achievable. Once a dome is modeled, tested, and approved, that framework can be reused for future projects—making each subsequent build faster and more predictable.

Interested in a compliant dome build in BC?

Phoenix Domes is actively collaborating with experienced energy advisors to streamline the path to permits. Contact us to explore your project.