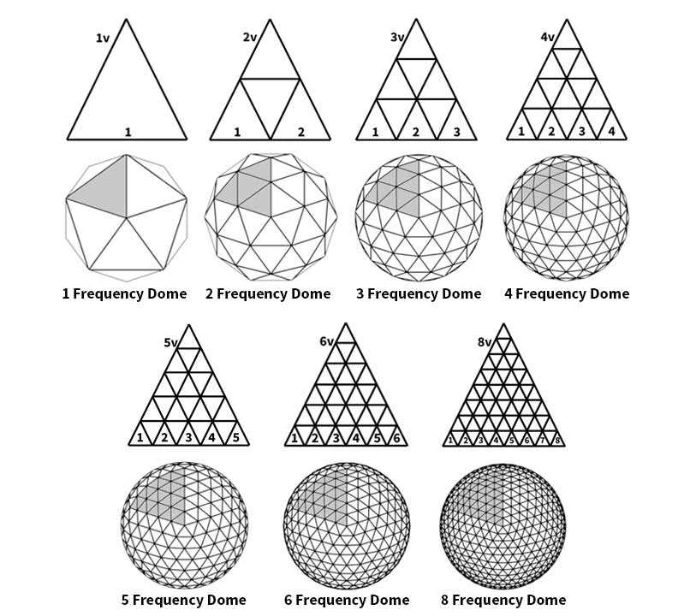

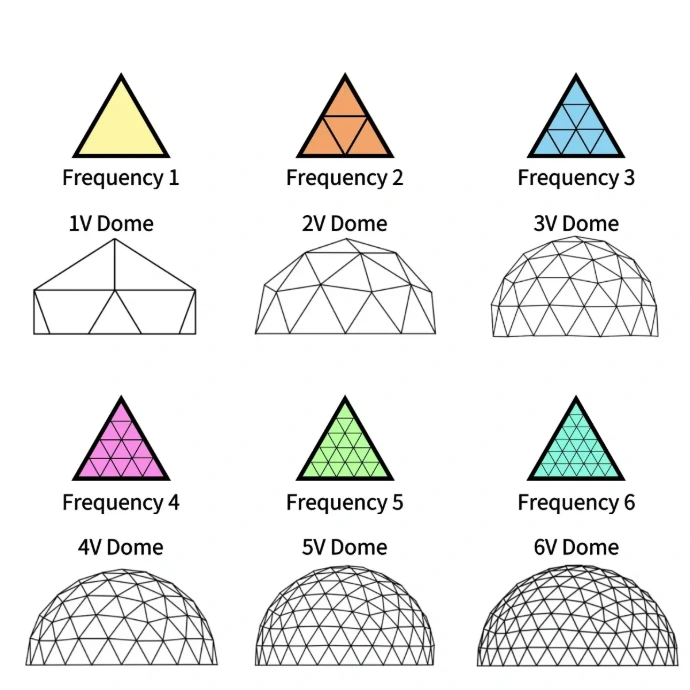

In dome construction, frequency (noted as “V” — like 2V, 3V, 4V) refers to how many times each triangle in the dome’s basic shape is subdivided. The result is a more curved structure made up of many smaller triangles.

But here’s the key thing:

Frequency isn’t something customers need to choose.

Our expert team determines the ideal frequency based on:

Dome type: glamping, event, or glass dome

Dome size

Structural performance requirements

Material type (like polycarbonate vs. glass vs. fabric)

Environmental loads, such as snow or wind resistance

This ensures each dome is engineered for maximum safety, functionality, and efficiency — without you needing to worry about the technical math behind it.

How We Use Frequency in Our Dome Designs

We select frequency based on what’s best for the structure, not personal preference. Here’s how we approach it across our two core product lines:

Glamping Domes

Dome Size | Frequency | Why We Use It |

5 m / 16′ | 2V | Simplified structure, efficient for easy setup and spaciousness glamping |

6–8 m / 20′–26′ | 3V | Excellent balance of strength and simplicity |

9–10 m / 30′–33′ | 4V | More triangles = affordable, stronger large dome |

11 m / 36′+ | 5V/6V/Lamella | More complexity for extra-large structures |

✅ We increase frequency as the dome gets larger or when structural demands (like snow load or insulation needs) require it.

💡 Fun Fact: Our 5m 2V dome is taller than typical 2Vs — thanks to a smart extra layer that boosts vertical clearance.

Glass Domes

Glass domes need higher frequency to support rigid panels and ensure panels aren't too large or heavy.

Dome Size | Frequency | Why We Use It |

5–7 m | 3V | Keeps glass panels within manageable size and weight |

8–9 m | 4V | Creates smoother curvature with safe glass dimensions |

10–11 m+ 12-13m | 5V 6V then Lamella | More triangles = more joints = stronger glass structure |

We also consider standard material dimensions (like 4x8’ sheets for interior paneling) to minimize waste and optimize cost without sacrificing quality.

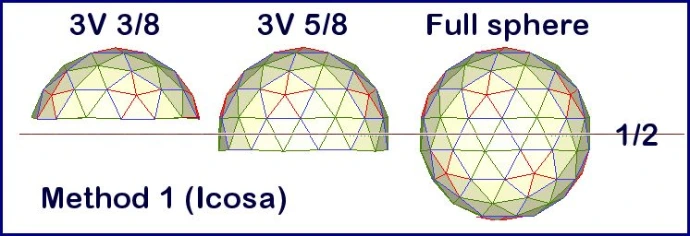

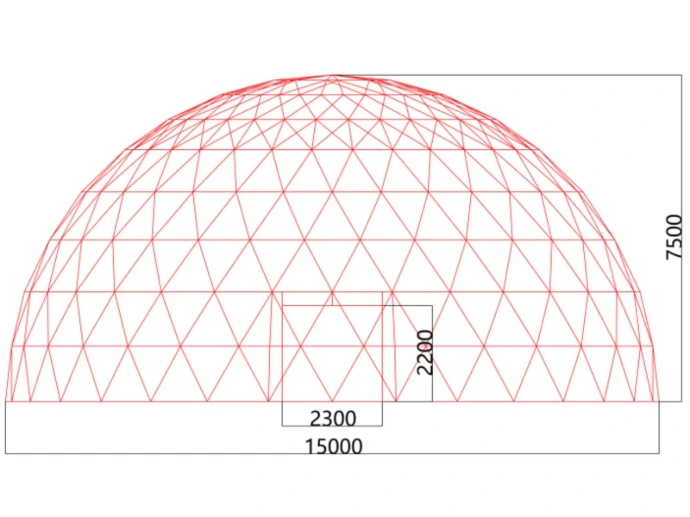

Fun Fact: Our odd-numbered frequency domes are somewhat taller than a half sphere, whereas the even number frequency domes are exactly a half sphere. See picture

Lamella Domes:

When “Higher Frequency” Stops Making Sense

As geodesic domes get larger, increasing frequency is one way to keep panel sizes manageable and improve curvature, but there’s a tipping point where the structure becomes too complex to assemble efficiently. That’s where lamella dome geometry becomes a smarter option for large-span builds.

A lamella structure forms a dome using a repeating, crisscrossed diamond (rhombic) grid of short members arranged across a curved surface, a type of gridshell. This system is well-known for spanning very large spaces with repetitive components, which is a big reason it has been used historically in large roof and dome applications.

Geodesic Frequency vs. Lamella Design

(Key Differences)

Geodesic frequency (2V, 3V, 4V…)

- Built from triangles created by subdividing a base geometry; higher “V” means many more unique parts and connections.

- As frequency rises, piece counts climb fast, sorting becomes more demanding, and layout mistakes are easier to make on site.

- We typically don’t go beyond 6V because 7V–8V becomes extremely time-consuming to organize and assemble in real-world builds.

Lamella geometry:

A type of ‘Lattice Dome

- Built from a repeating **diamond-pattern grid** of members that creates a smooth curved shell.

- Instead of “frequency,” lamella domes are organized by layers (rings) — and each layer can use a consistent, repeatable strut set, making the build much easier to manage with good sorting and staging.

- Because the geometry is easier to follow, it’s often simpler to involve more helpers without requiring everyone to understand complex dome math.

Faster, Safer Setup for Large Domes (Often Top-Down)

For many large lamella domes (especially event domes), setup can be done top-down using a crane truck.

You begin at the top section, and the crane lifts and holds the structure while teams assemble the next ring(s) from ground level.

This approach can be faster than extensive scaffolding work and can keep the crew safer and more efficient, especially on large, time-sensitive installations.

Why We Use Lamella for Large Event Domes

(And Sometimes Residential/Glass)

- Larger residential domes where you want big interior volume without excessive assembly complexity

- Very large glass domes, where keeping the build process organized and scalable becomes critical

Why We Still Use Geodesic Geometry for Smaller Glass Domes

For smaller glass domes, we strongly prefer geodesic frequency because it supports highly consistent, repeatable fabrication. In our geodesic glass dome models, we can standardize around a precise aluminum framing approach that stays consistent across the dome for that design — which streamlines manufacturing, improves fit-up, and simplifies installation compared with geometries that require more varied connection conditions.

Why This Approach Matters

Instead of making customers pick a technical frequency they might not understand, we provide expert-designed dome systems optimized for:

Structural integrity

Aesthetic appeal

Ease of manufacturing and installation

Longevity and environmental resilience

🛠️ We handle the frequency math — so you can focus on the experience, look, and performance of your dome.